British car industry struggling

Government urged to focus on industry's future or lose it

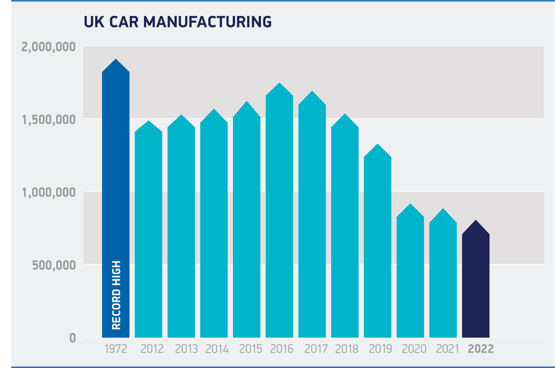

UK car production has sunk to its lowest level since 1956.

That’s according to new figures from the Society of Motor Manufacturers and Traders (SMMT).

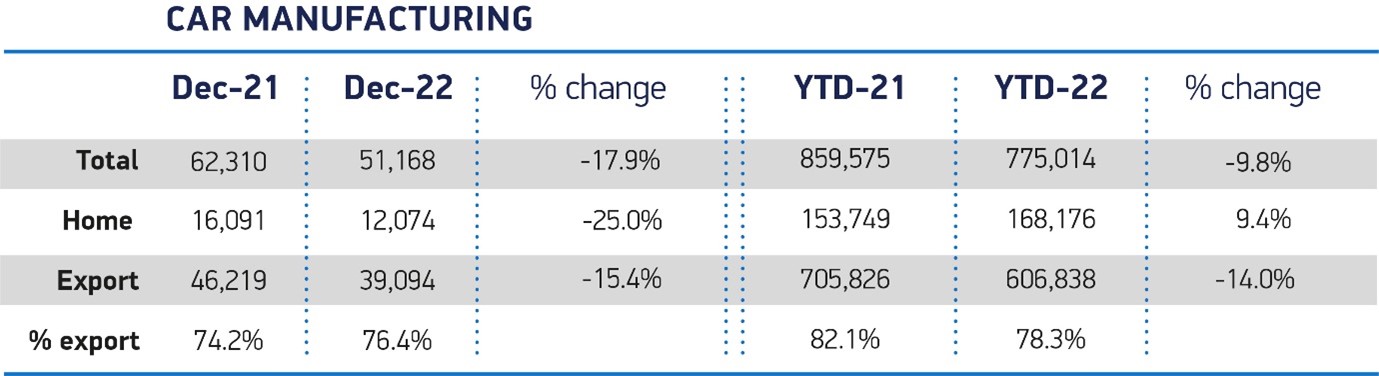

Last year, the UK produced just 775,014 cars. This is only slightly more than the 707,594 units produced in 1956, the toughest post-war year for British manufacturers.

Worrying traffic news

As well as the growth of strong foreign competition, the country was struggling with a credit squeeze, increased issues due to Brexit, a growing reliance on exports and labour disputes.

In 2022, the SMMT says the global shortage of semiconductors was also a factor.

Issue in Chinese manufacturing and supplies due to Covid lockdowns were also a significant issue.

Year-on-year, UK car production declined by 9.8% in 2022, with 84,561 fewer units built on the previous year. The total was 40.5% off the 1,303,135 cars made pre-pandemic in 2019, equivalent to a loss of more than half a million cars.

This has led to descriptions of the prospects for UK car manufacturing being labelled “precarious”. Pressure is mounting to accelerate investment in zero-emissions electric vehicle (EV) production following 2022’s 9.8% sector decline.

Plugging into future success

More investment is needed to secure a slice of the global EV automotive manufacturing future.

“Much can be made about the good news of the supply constraints easing,” says What Car? editorial director Jim Holder. “But the long-term prospects of the industry remain precarious”.

“If the UK is serious about meeting its electric vehicle ambitions, and serious about remaining a manufacturing hub, urgent investment into electric vehicle battery manufacturing and the supply sector is needed.

“If the Britishvolt collapse taught anything, it’s that the Government should be at the forefront in driving this investment.”

Richard Peberdy, UK head of automotive at KPMG, says “the race for countries to be seen as world leaders in electric vehicle production is well underway”.

This depends largely “on investment in battery manufacturing and related skills. At this time, it remains uncertain where that is coming from”.

Semi success

Independent forecasts suggest an easing semiconductor shortages will help UK car and van output. This could rise 15% to 984,000 units in 2023 (842,200 cars and 141,800 vans) with a million vehicles built annually by 2025.

However, fresh SMMT analysis laid bare the increasingly important role of electrified vehicle production to those predictions.

Since 2017, the value of EV, PHEV and HEV exports has risen seven-fold, from £1.3bn to more than £10bn.

As a result, electrified vehicles represent 44.7% of the value of all UK car exports, up from a mere 4.1% in the same period.

The export value of EVs alone is up more than 1,500%, from £81.7m to £1.3bn.

But in 2022, publicly-announced automotive manufacturing sector investment was down from £4.9bn (2021) to £4.5bn. This comes despite major new commitments to electrification in Crewe and Merseyside.

A need for national focus

SMMT chief executive Mike Hawes said: “These figures reflect just how tough 2022 was for UK car manufacturing, though we still made more electric vehicles than ever before – high value, cutting edge models, in demand around the world.

“The potential for this sector to deliver economic growth by building more of these zero emission models is self-evident, however, we must make the right decisions now.

“This means shaping a strategy to drive rapid upscaling of UK battery production and the shift to electric vehicles based on the UK automotive sector’s fundamental strengths – a highly skilled and flexible workforce, engineering excellence, technical innovation and productivity levels that are amongst the best in Europe.”